Whether it’s seaweed packaging or bricks made from cow dung, a new crop of award-winning product designers are turning away from fossil-based plastics and chemicals

Glance around your home and it won’t be long until you spot something set to outstay its welcome. From ziplock bags to period pads, for almost everything we consume, a sustainable alternative is needed.

That’s the goal of the Make It Circular Challenge, run by international organisation What Design Can Do. It called on entrepreneurs and creatives to submit project ideas that are built to last, work with nature, and use pre-existing resources. More than 650 entrepreneurs answered the call with innovative strategies for building a more circular society.

Here are four of the 13 inspiring winners.

1. Biodegradable shoes

David Roubach has been wearing the same pair of sandals for two and a half years now. It doesn’t sound extraordinary until you account for the fact that they’re completely biodegradable.

“I think it’s funny that we as humans have invented so much, but for the end use of products, we only have one solution called recycling,” Roubach, the founder of Israel-based Balena, explains. He calls his innovation ‘biocycling’.

Against the backdrop of the fashion industry, where 60 per cent of all material made into clothes is plastic, Balena has developed a bioplastic that ticks three boxes. Not only is it comfortable, sturdy and easy to mould, it’s also made from natural and renewable materials, and is entirely compostable in industrial facilities.

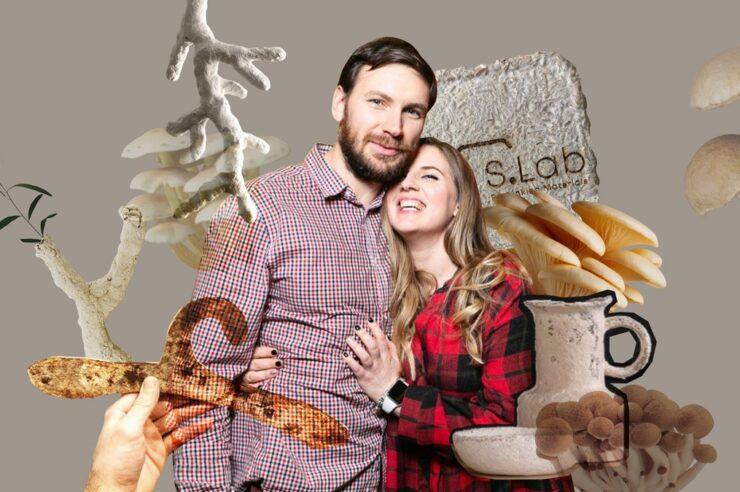

The company’s first run of shoes (main image), produced as a proof of concept, sold out, with customers able to return them for recycling when they’re finished with them. But that’s just the beginning. Roubach hopes to work on new materials, collaborations, and even certifications for products using Balena’s materials.

But, he stresses, it all starts with consumers: “The question we need to ask every time we buy something is: ‘what’s going to happen to it at the end?’”

2. Seaweed packaging

Seaweed can have a positive impact on ecosystems as it captures CO2. Image: mujō

Juni Sun Neyenhuys believes that packaging should only last as long as we need it. Whether it’s a bag of salad leaves or a snack wrapper, once you’ve eaten the contents it should be thrown on the compost heap to biodegrade naturally and harmlessly.

That’s the modus operandi of Germany based mujō, a company she co-founded with Annekathrin Grüneberg, which replaces conventional packaging with seaweed. Unlike land-based materials, seaweed doesn’t need agricultural land, watering, or pesticides.

“All that bad stuff is not needed when you grow seaweed,” Neyenhuys explains. “It has a positive impact on ecosystems because it [captures] CO2, and it grows really, really fast. It can grow up to 60 centimetres in a day.

“[But] what is really important is that we don’t make the same mistakes in aquaculture as we did in agriculture.” For example, harming biodiversity through mono-cropping, or relying heavily on synthetic fertilisers.

With funding now in place, the team is working on product development, and hopes to get its packaging on shelves within the next 12-18 months.

3. Plastic-free pads

Saathi's pads take only six months to decompose after use. Image: Saathi

“Our business model is the first of its kind,” Tarun Bothra, one of the co-founders of Saathi, based in India, tells Positive News. The company makes sanitary pads, but crucially, without the 3.4g of plastic that’s usually in each one.

“It’s a completely circular business model, where we are not taking anything at all which is manmade or from a resource that’s depleting.”

Instead, the company uses banana and bamboo fibres, sourced from agricultural waste. Antibacterial properties of these materials make them a perfect fit for period products, and the pads take only six months to decompose after use.

Saathi has also donated over a million of its pads to Indian women – only 36 per cent of whom have access to menstrual products.

“We’re trying to propose a more holistic approach to menstrual hygiene, as well as health and sustainability,” says co-founder Kristin Kagetsu. While there’s a long way to go, she believes a shift in mindset is taking place.

“We’ve seen fathers come and talk about the product with their daughters, we’ve seen guys buy it for their friends. That’s definitely a new experience for us.”

4. Bricks made from cow dung

Coolbricks' production cuts carbon emissions by 90 per cent. Image: Tu Delta

CoolBricks are different to other building materials – but you wouldn’t know it. The first reaction of masons when given a brick to hold is that they can’t believe it doesn’t contain cement, says founder Emile Smeenk. Unlike everyday bricks, these ones are not fired or baked and are 100 per cent recyclable.

“CoolBricks are composed of soil and the active ingredients of cow dung,” explains Yask Kulshreshtha, head of research and development at the startup, which is based in the Netherlands and Uganda.

“Traditionally, many countries have used cow dung for making houses,” she continues, explaining that her team has taken this core idea, and modernised it.

While the mud is often cut from wetlands, leading to habitat loss, CoolBricks’ method can incorporate any type of soil as the base ingredient. It also pays farmers a fair price for their cow dung.

The result is a brick that is 20 per cent stronger than traditional mud bricks, cuts carbon emissions by 90 per cent and costs an impressive 50 per cent less.

“Circular innovation is about shortening supply chains and making it simple so that you can reuse local materials,” says Smeenk.

Main image: Balena